Fubar's GT Build

- Thread starter Fubar

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mark whats the cupcake pan for? :lol

Well he did say he feels like it's his birthday!

I haven't forgot about your question. I'm just waiting on some pictures of the adapter we made for this. I'll post up the CAD image today or tomorrow. I will post an actual picture of the adapter when the machine shop gives it to me.How did you get a ring gear for the starter onto that quad clutch

You can't have a real party without cupcakes.Mark whats the cupcake pan for? :lol

How did you get a ring gear for the starter onto that quad clutch

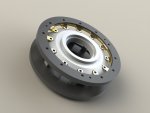

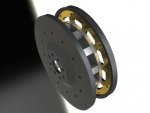

The "bottom" picture shows the flywheel in dark grey... the "top" pic show the starter gear ring as a dark grey solid ring (not teeth represented). It is attached to the clutch, that is shown light grey, by an adaptor piece that is shown as gold that bolts to the clutch housing and the starter ring.

MoTeC Magic

Spectator

Mark whats the cupcake pan for? :lol

I use them for keeping parts straight... mainly for fasteners. You can imagine having 4-5 cars in the shop that are extensive builds... all torn down pretty far... that it would be difficult to keep track of everything. They go into the pan and a sharpie labels that hole as to where and what they go to.

Works great!

That pan has our crate screws in it

Cheers

twobjshelbys

GT Owner

I use them for keeping parts straight... mainly for fasteners. You can imagine having 4-5 cars in the shop that are extensive builds... all torn down pretty far... that it would be difficult to keep track of everything. They go into the pan and a sharpie labels that hole as to where and what they go to.

Works great!

That pan has our crate screws in it

Cheers

Me too. I also use the little take-out salad chip dip containers with a lid if I'm going to be away for a while. Blue tape on the top that corresponds to the other side helps match things up.

ultrasportracing

GT Owner

MoTeC Magic

Spectator

Great idea for the clutch,, how much.??

Thanks, Not sure yet. As most of you know, the carbon-carbon clutches are not cheap. I've designed and set Mark's car up for a 4 disk. I should know final pricing in a few weeks.

If you look at the rendering, the flywheel is a new piece too. It is much larger in diameter than the new clutch. This is for street drivability. Keeping some weight in the flywheel helps when taking off from a dead stop, like pulling away from stoplights or stop and go traffic.

When racing, it is better it be as light as possible… Guys wanting them for the track, I'll make the flywheel a smaller diameter if desired. Not recommended for the street.

The carbon clutch is already dropping about 15lbs + off the stock clutch. This will have a dramatic effect on engine acceleration due to less rotational inertial. It will be similar to titanium rods and possible more.

Cheers

The weight difference was way more than 15lbs! That carbon clutch is ridiculous! It weighs nothing. If you taped the assembly together, you could toss it around with one hand.

ultrasportracing

GT Owner

I am sure you could sell the adapter for the clutch cover to ring gear in different off sets to suit 2/3/4 plate clutches is it for a 7.1/4" or smaller

Thanks, Not sure yet. As most of you know, the carbon-carbon clutches are not cheap. I've designed and set Mark's car up for a 4 disk. I should know final pricing in a few weeks.

If you look at the rendering, the flywheel is a new piece too. It is much larger in diameter than the new clutch. This is for street drivability. Keeping some weight in the flywheel helps when taking off from a dead stop, like pulling away from stoplights or stop and go traffic.

When racing, it is better it be as light as possible… Guys wanting them for the track, I'll make the flywheel a smaller diameter if desired. Not recommended for the street.

The carbon clutch is already dropping about 15lbs + off the stock clutch. This will have a dramatic effect on engine acceleration due to less rotational inertial. It will be similar to titanium rods and possible more.

Cheers

MoTeC, very interesting design!

Because we all know Mark will be pulling some high engine speeds (and we are concerned about his well-being), just curious as to your calculated burst speed of the new flywheel, and flywheel/clutch assembly? These can be very ugly failures especially at high speeds. Analytical calculations or have actual verification tests been conducted? Flywheel material?

Sure you have these bases covered. Would be interesting to know for (for me and) our other readers. Thanks!

Hmmm, yes Shawn... what is the burst speed of this design?

(frantically googling 'clutch burst speed' wtf is burst speed?)

(frantically googling 'clutch burst speed' wtf is burst speed?)

MoTeC Magic

Spectator

I am sure you could sell the adapter for the clutch cover to ring gear in different off sets to suit 2/3/4 plate clutches is it for a 7.1/4" or smaller

We could, though, the more offset in the ring gear adaptor the more bending moment. I'd like to keep the adaptor, as much as possible, in tension. For 2 and 3 disk clutches I'd probably just make the flywheel extend further away from the crank flang... Basically like adding a spacer behind the flywheel, between it and the crank but as one piece.

Cheers

MoTeC Magic

Spectator

MoTeC, very interesting design!

Because we all know Mark will be pulling some high engine speeds (and we are concerned about his well-being), just curious as to your calculated burst speed of the new flywheel, and flywheel/clutch assembly? These can be very ugly failures especially at high speeds. Analytical calculations or have actual verification tests been conducted? Flywheel material?

Sure you have these bases covered. Would be interesting to know for (for me and) our other readers. Thanks!

We’ve run these 7.25” (forgot to confirm the size in post above) carbon-carbon clutches in our pro drag cars for about 7 years… see below. We turn them in excess of 12,000RPM. Mark will be pressed to see 9k, that will be the absolute RPM limit for his build. The clutch is smaller in diameter than the stock or other aftermarket clutches so the forces on it are less too. Another good thing is the weight is less with the carbon clutch than a stock style clutch so it stores less energy. A stock clutch or one like it coming apart would do far more damage due to the significantly increased mass.

Everything is steel with the exception of the clutch basket and pressure plate. They are titanium. The ring gear is stock. Everything will have very high quality ARP fasteners in it. Installed correctly, and operated correctly, there shouldn’t be any issues.

Lots of pics for those that like images.

We made these clutches. Below are images of a few of the vehicles and clutches that we have run in some pretty serious drag applications. The first car depicted below is a RWD Celica with a 152cuin 4 cyl with a billet head that we made, we also converted the motor from chain to belt drive… along with many other custom parts on the car. The engine is makes about 1600hp, the car has run 6.90s.

This clutch is what I wanted to show you. It is built off of a Tilton center. We made the disk, the stands, and the hat. The only thing really different from Mark’s and the first one shown, that is a 4 disk also, is that the fingers are centrifugally driven to apply the pressure plate and engage the clutch. It acts much like a go cart clutch, but comes in at a much higher RPM. The clutch doesn’t lock up till 8000rpm. A street carbon-carbon clutch and a road race clutch have a diaphragm spring and peddle to engage and dis-engage the clutch. The other difference on the race clutch is the stands are adjustable as the clutch wears. Carbon does not wear much and last longer than other clutch materials. It can also take significantly more slipping, though it does generate a lot of heat when slipped excessively. Good thing is, carbon is already burned up

This was more to show the experience we have with carbon clutches and show something neat relative to the same subject... I hope you find this interesting

Cheers

Here is the ProMod 4cyl… 286 cubic inch, currently producing about 3000hp. It’s half of a BBC with a custom billet 4v head and block. Weighs 1900lbs. We made this clutch too. Shown with 6 driven disk and 7 driving disk... tihs was not enough friction material for our power so we added 3 more disk each and are now 9 driven disk 10 driving disk.

Wow, is about all that comes to mind..... Oh yeah, nice transporter / toter in pic 1.....

+1 on both counts