Power steering pump hose leak

- Thread starter Sinovac

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

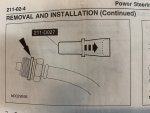

To close out this thread for future reference, I’ll share that the leak was not coming from the o-ring. There was an extremely tiny pinhole in the hard line below the o-ring where the ferrule contacts the flare.

I put a vacuum on it and heard a faint hiss. I then pressurized the line with water. Even knowing where it is, I could barely see it.

You can temporarily put an o-ring below the flare to diagnose this. Also, keep in mind that if you have a leak at the pressure line going into the pump, tightening the ferrule can actually make the problem worse by cracking the line. It’s not a compression type fitting, it’s an o-ring that rides in a bore. The ferrule just needs to be tight enough to keep the line in place.

Now I just need to find a new pressure line at a decent price. MSRP is about $1k. Ack

I put a vacuum on it and heard a faint hiss. I then pressurized the line with water. Even knowing where it is, I could barely see it.

You can temporarily put an o-ring below the flare to diagnose this. Also, keep in mind that if you have a leak at the pressure line going into the pump, tightening the ferrule can actually make the problem worse by cracking the line. It’s not a compression type fitting, it’s an o-ring that rides in a bore. The ferrule just needs to be tight enough to keep the line in place.

Now I just need to find a new pressure line at a decent price. MSRP is about $1k. Ack

Last edited:

- Aug 8, 2007

- 5,256

nice job finding that leak ,, I know sometimes they can be pretty hard to find .. im dealing w ps leak in my daily driver now a 09 audi s8 I am no looking forward to work on that car as it is impossible to do anything without first removing half the engine compartment

nice job finding that leak ,, I know sometimes they can be pretty hard to find .. im dealing w ps leak in my daily driver now a 09 audi s8 I am no looking forward to work on that car as it is impossible to do anything without first removing half the engine compartment

We're fortunate that the GT is fairly easy to work on. Good luck with your project.

Maybe. I bit the bullet and bought the OEM hose for about $650.

- Aug 8, 2007

- 5,256

ouch! I think you got hosedMaybe. I bit the bullet and bought the OEM hose for about $650.

ultrasportracing

GT Owner

I’m going to do just that and save it as a spare. These parts are getting too expensive to toss.

I'm currently dealing with a leaking HP power steering hose on my Porsche Cayman R. And yes it's been a pain dealing with all the parts I had to take off to get to the hose. AC compressor was the biggest problem as the hose went underneath it.nice job finding that leak ,, I know sometimes they can be pretty hard to find .. im dealing w ps leak in my daily driver now a 09 audi s8 I am no looking forward to work on that car as it is impossible to do anything without first removing half the engine compartment

- Aug 8, 2007

- 5,256

gota love german engineering ....I'm currently dealing with a leaking HP power steering hose on my Porsche Cayman R. And yes it's been a pain dealing with all the parts I had to take off to get to the hose. AC compressor was the biggest problem as the hose went underneath it.

driving them is fine, working them not so much

We've seen this twice now - it seems the pipe cracks at the point where your droplet is in the picture - as the most tightly formed point I presume it's the weakest.

We had a local hydraulic company make up a new hose for us at a cost of around $30...

We had a local hydraulic company make up a new hose for us at a cost of around $30...

We've seen this twice now - it seems the pipe cracks at the point where your droplet is in the picture - as the most tightly formed point I presume it's the weakest.

We had a local hydraulic company make up a new hose for us at a cost of around $30...

F***!

- Aug 8, 2007

- 5,256

yes, the not so smart ones doPeople actually own German cars past the warranty?

im glad to report that my ps is fixed (again) It was one of the factory lines that busted I replaced a piece of the line with a new line sourced from Oreilys parts store for a cool 12 dollars. lets see how long this fix lasts as Im sure the new hose wont stand up to the pressures of german pumps. I think the pressure in the ps system of audi is somewhere in the neighborhood of the pressure at the exhaust manifold of the space shuttle.

Last edited: