Brembo Two Piece Rotors

- Thread starter Enzo101

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

sahlman

Ford GT Team Alumni

Girodisc McLaren MP4-12C Rear 2-piece Rotors - Ahlman Performance

The Girodisc system is a direct replacement for the OE disc. No modifications are necessary. The disc will bolt directly to the car and work with OE calipers perfectly. By upgrading your brakes with lightweight high performance replacements, your factory bias is maintained as well as your ABS...

Thank you, Andy. I just saw your thread Enzo101. Andy is correct above on the Girodiscs's for FGT. Such a great all American made product for pedal feel, cooling, lack of fade, weight and durability. We run them hard on our V10 R8 as well on the road or the track (Road America) and just change the front pads between the two (because of noise with the track pads). Andy picked the right links. I have no idea why the description is showing up McLaren so I have to get that fixed.I have not tracked it enough (and likely wont ever) to need to replace the rotors, but if I did, I would keep the hat, and change only the rotor.

If you are looking for some, maybe talk to Scott Ahlman, he represents them in addition to his shocks @sahlman

Girodisc Front 2-piece Rotors for McLaren MP4-12C - Ahlman Performance

The Girodisc system is a direct replacement for the OE disc. No modifications are necessary. The disc will bolt directly to the car and work with OE calipers perfectly. By upgrading your brakes with lightweight high performance replacements, your factory bias is maintained as well as your ABS...www.ahlmanperformance.com

sahlman

Ford GT Team Alumni

Heres the Pagid yellows that are for serious track work and when hot are AMAZING in bite/feel.

Still fine for street use.

I bought the titanium shims, but on the new Pagid yellows I couldn't get them to slide in (only needed 1mm per rotor to fit them in) so couldn't used them for the first outing.

Would've been nice to have tried the shims as by the end of the track day (Sebring) the drivers rear caliber changed colour due to high temps.

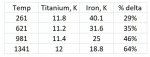

While I understand the theory of using a thermal barrier material (Titanium shim) to limit the heat transfer from the brake pad into the brake caliper piston, my personal experience running these shims on my race car did not prove beneficial. Titanium (as a shim material) does have a lower thermal conductivity (Symbol K and units: BTU/(hour foot deg F)) than iron used for the brake rotor ring. Titanium has about 30% conductivity at 261F and about 64% at 1341F relative to the iron brake rotor. Thus K is a function of operating temperature. The higher the K value the more heat is able to be conducted through the material. See chart below-

Whether a thermal barrier shim is used or not, heat is generated by friction of the pad against the brake rotor. Where this heat goes is affected by shim use. Inhibiting heat transfer from the pad backing into the caliper pistons, caliper body and caliper brake fluid forces the heat to remain in the rotor and pad. The higher temperature operating conditions (caused by shim use) could generate adverse disc thermal gradient conditions increasing possible rotor warpage. As the table indicates at the higher rotor operating temperature, K is reduced and further limits it ability to shed internal heat to external sources. And these conditions force the brake pad to operate at higher temperature conditions as well. Maybe the disc rotor and pad materials are designed for these higher thermal conditions or maybe not.

I was running DBA 2-piece front rotors and PFC 7781.97.15.44 pads which are both certainly higher performance hardware than would be expected OE. I could definitely see bluing of the rotor material and visual pad indications of higher temperature operation. Perhaps this increased temperature environment was within the design envelope of my upgraded rotor/pad hardware as I did not encounter any high temperature fade or any perceived better braking performance. I could not see any performance delta so did not choose to use the titanium shims.

My experience take-away was to allow heat flow into the caliper (I was running Brembo calipers which are well designed for the thermal environment) and more importantly, use fresh DOT4 brake fluid which offers superior wet boiling point protection. Just my 2 cents….

Last edited:

sahlman

Ford GT Team Alumni

What is pictured above is their new B-M6 Caliper and significantly upgraded rotors in size (diameter and thickness), slotted, two-piece floating, cooling. These new calipers as a result are bigger, wider and more rigid with all internal hydraulic passages (no external tubing). The system comes with brackets and hardware to mount to the stock knuckles. Because of the large size upgrade this system will NOT fit in the stock front wheels/sizes (even aftermarket) and I am not positive on the rears. I have the cross sections of the calipers in position to check versus aftermarket wheels.Scott, is the new Brembo Caliper a performance upgrade? Or just another shape that gets the job done the same.

To my untrained eye, it looks like it might be lighter and cool off faster.

.

- Front

- Stock = 355 mm x 32 mm = first line of the table below for the Brembo two piece slotted floating rotor with aluminum hat

- Brembo Upgrade = second line below = 390 mm x 35 mm

- Rear

- Stock = 335 mm x 32 mm = first line of the table below for the Brembo two piece slotted floating rotor with aluminum hat

- Brembo Upgrade = third line below = 380 mm x 32 mm

For those that want to stay stock with an upgrade in cooling, fade, better feel and less rotating mass then the Girodiscs floating two piece rotors that Specracer is running on his FGT are extremely good at a great price.

Indy, since you’re an engineer, I know you know how to calculate heat transfer, but I think you overlooked a factor in your discussion. Heat transfer is a function of K value, temp differential, AND thickness of the shim (per unit area). I assume the titanium shims are pretty thin, on the order of .010” to .020”? If so, then the shims are very thin relative to their area, and would not reduce total heat transfer significantly. Your experience seems to bear this out.

Furthermore, I suspect the K value of the brake pad friction material is much lower than the shims (I tried to do a quick internet search but didn’t find any of those K values). Since the pad thickness is on the order of 1/4”, the heat passing from the friction interface of the rotor and pad, through the pad material and backing plate will already be greatly reduced by the time it gets to the shim. Therefore, the shim’s contribution to the insulation between the friction surface and the caliper probably is close to nil. I know from tracking several of my cars over the years that the calipers get damn hot too, but not nearly as hot as the rotors.

And why wouldn’t you choose DoT 5.1 over DoT 4?

Furthermore, I suspect the K value of the brake pad friction material is much lower than the shims (I tried to do a quick internet search but didn’t find any of those K values). Since the pad thickness is on the order of 1/4”, the heat passing from the friction interface of the rotor and pad, through the pad material and backing plate will already be greatly reduced by the time it gets to the shim. Therefore, the shim’s contribution to the insulation between the friction surface and the caliper probably is close to nil. I know from tracking several of my cars over the years that the calipers get damn hot too, but not nearly as hot as the rotors.

And why wouldn’t you choose DoT 5.1 over DoT 4?

Pete, I love your technical questions! It shows you are thinking about what I posted and forces me to go back and rethink what I said relative to your question(s). Your questions are certainly valid.

I assume the titanium shims are pretty thin, on the order of .010” to .020”? If so, then the shims are very thin relative to their area, and would not reduce total heat transfer significantly. Your experience seems to bear this out.

Yes, the Girodisc Titanium shims I purchased and tried were on the order of 0.020” – 0.030” thick. From their website, "The problem of brake fluid boiling is simply traced to heat transferring from the rotors and pads directly into the fluid through the caliper pistons. When brake fluid boils, it releases air that is normally part of the molecular structure of the fluid. This air is compressible of course, and the brake pedal goes to the floor instead of moving the caliper pistons. Production cars tend to suffer from this on track days more as they don't usually have the extensive cooling duct and exotic brake materials as true racing cars. True racing only brake calipers generally come with titanium caliper pistons for one reason. Titanium as a material, has low thermal conductivity. This means that it is very bad at transferring heat. Which is good if you are trying to keep your fluid cool.

The Girodisc solution to help prevent fluid boiling is to use a thin titanium shim placed between the pad back and the pistons, to keep the braking heat from transferring into the pistons and fluid. Here is a comparison of materials and their relative thermal conductivity ratings

Titanium 6AL-4V 6.7 W/mk

Steel 52 W/mk

Aluminum 130 W/mk

You can see that Titanium will transfer far less heat than steel and especially aluminum. For cars that are going to see hard or multiple track days, these shims are cheap protection from loosing the pedal due to boiling at the wrong time and making the day very expensive.

Water jet cut to exact size, no cutting, grinding, or swearing involved."

To your point, yes the shims were thin relative to the brake pad friction material (approx 0.47” thick which has a low K value as you correctly point out) and the steel backing plate (approx 0.120”), but the generated BTU’s still flow from the steel backing plate into the caliper pistons (thru conduction reduced somewhat by the low K Titanium shim) and to the caliper structure (thru radiation). Emissivity values for rotor steel (about 0.64) and Titanium shim (0.51 – 0.61) for typical rotor temperatures are about the same but vary due to the material surface finish. Assume radiation heat transfer is a push. So even though the shims are thin, they do provide a barrier to Q (heat flow) into the brake pistons. Note too that the small area which you reference for the shims, is numerically equal to the same area the unshimmed pistons would have contacting the steel backing plate. And my experience did NOT bear out the insignificance of the Titanium heat shield barrier. I did see evidence the generated braking heat was retained in the brake rotor (bluing steel) and thermal indications on the pad material. So even though the shims are relatively thin, they did appear to (as advertised) limit Q into the caliper pistons and caliper brake fluid.

Now onto the brake fluid question, “And why wouldn’t you choose DoT 5.1 over DoT 4?”. Excellent question and I had to think about that one cause using DOT4 just rolled off the top of my head. See also Best DOT 5.1 Brake Fluid of 2021: Reviews & Buying Guide (lastviews.com) As I am sure you know but for members not familiar with brake fluid, all automotive brake fluid used in North America (NA) is controlled by US Department of Transportation, Federal Motor Carrier Safety Administration (FMVSS) , Part 571, Standard No. 116; Motor vehicle brake fluids. Brake fluids sold to consumers in bottles/cans etc. or installed in cars sold in NA must conform to the technical specifications detailed in this Standard. The Standard is quite lengthy and covers all the different “types” of fluids which can be used, i.e. DOT3, DOT4, DOT5 and DOT5.1. These different types of fluids all have different requirements per the Standard. It is beyond the scope of this post to delineate the differences between all the different flavors so I will focus on the question fluids DOT4 and DOT5.1.

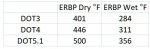

FMVSS 571.116S5.1.1 defines the term ERBP (Equilibrium Reflux Boiling Point) and gives minimum wet and dry boiling point standards which must be met to be classified in a given DOTx category. See table below. My key focus over the years of using brake fluid in race cars is the “wet” boiling point as this boiling point value is where the fluid properties go after installation and in-service use. Brake fluid is hygroscopic by nature (absorbs atmospheric water) and as the fluid ages in the vehicle system and absorbs water, its boiling point erodes to the minimum wet boiling point value. Thus always use a new unopened container of brake fluid when flushing or adding fluid to the system.

As you correctly opine, just fill your system with DOT5.1 fluid which offers the best boiling capacity of all the grades. You are right!

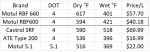

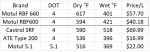

Understand FMVSS 571.116 dictates MIMIMUM standards the fluid manufacturer must meet to brand his fluid as DOTx. If he can economically blend a fluid which exceeds all the minimum DOTx requirements, he certainly can do so. And the highly reputable fluid manufacturers certainly do this. I have tabulated a few popular brake fluids (DOT4 and DOT5.1) indicating under which DOTx the fluid is sold, the dry/wet boiling points and cost per liter. Data is pulled from https://www.pegasusautoracing.com/group.asp?GroupID=BRAKEFLUID

As is obvious, all of the selected DOT4 fluids exceed the DOT5.1 standards by a significant amount. In fact the Motul 5.1 fluid while exceeding all the required FMVSS 571.116 boiling point requirements falls way short of what you can get in a DOT4 fluid. The only advantage is the lower cost of the DOT5.1. I typically use the DOT4 Motul RBF600 which offers reasonable price for the highest wet boiling point fluid. I really liked the DOT4 ATE Super Blue Racing fluid (same as Type 200) which had a blue color to the fluid. Someone filed a complaint against this product because as a DOT4 fluid, it did not conform to FMVSS 571.116S5.1.14 Fluid Color and the product is no longer available here in NA. Only the ATE Type 200 (amber color per the Specification) is now available and is a strong candidate due to its properties vs. cost. Castrol SRF does carry a higher wet boiling point fluid at a +74% cost premium on which I choose to pass.

So, Pete that is why I would use one of the many economical DOT4 fluid candidates. Hope this helps and I have not bored our audience.

I assume the titanium shims are pretty thin, on the order of .010” to .020”? If so, then the shims are very thin relative to their area, and would not reduce total heat transfer significantly. Your experience seems to bear this out.

Yes, the Girodisc Titanium shims I purchased and tried were on the order of 0.020” – 0.030” thick. From their website, "The problem of brake fluid boiling is simply traced to heat transferring from the rotors and pads directly into the fluid through the caliper pistons. When brake fluid boils, it releases air that is normally part of the molecular structure of the fluid. This air is compressible of course, and the brake pedal goes to the floor instead of moving the caliper pistons. Production cars tend to suffer from this on track days more as they don't usually have the extensive cooling duct and exotic brake materials as true racing cars. True racing only brake calipers generally come with titanium caliper pistons for one reason. Titanium as a material, has low thermal conductivity. This means that it is very bad at transferring heat. Which is good if you are trying to keep your fluid cool.

The Girodisc solution to help prevent fluid boiling is to use a thin titanium shim placed between the pad back and the pistons, to keep the braking heat from transferring into the pistons and fluid. Here is a comparison of materials and their relative thermal conductivity ratings

Titanium 6AL-4V 6.7 W/mk

Steel 52 W/mk

Aluminum 130 W/mk

You can see that Titanium will transfer far less heat than steel and especially aluminum. For cars that are going to see hard or multiple track days, these shims are cheap protection from loosing the pedal due to boiling at the wrong time and making the day very expensive.

Water jet cut to exact size, no cutting, grinding, or swearing involved."

To your point, yes the shims were thin relative to the brake pad friction material (approx 0.47” thick which has a low K value as you correctly point out) and the steel backing plate (approx 0.120”), but the generated BTU’s still flow from the steel backing plate into the caliper pistons (thru conduction reduced somewhat by the low K Titanium shim) and to the caliper structure (thru radiation). Emissivity values for rotor steel (about 0.64) and Titanium shim (0.51 – 0.61) for typical rotor temperatures are about the same but vary due to the material surface finish. Assume radiation heat transfer is a push. So even though the shims are thin, they do provide a barrier to Q (heat flow) into the brake pistons. Note too that the small area which you reference for the shims, is numerically equal to the same area the unshimmed pistons would have contacting the steel backing plate. And my experience did NOT bear out the insignificance of the Titanium heat shield barrier. I did see evidence the generated braking heat was retained in the brake rotor (bluing steel) and thermal indications on the pad material. So even though the shims are relatively thin, they did appear to (as advertised) limit Q into the caliper pistons and caliper brake fluid.

Now onto the brake fluid question, “And why wouldn’t you choose DoT 5.1 over DoT 4?”. Excellent question and I had to think about that one cause using DOT4 just rolled off the top of my head. See also Best DOT 5.1 Brake Fluid of 2021: Reviews & Buying Guide (lastviews.com) As I am sure you know but for members not familiar with brake fluid, all automotive brake fluid used in North America (NA) is controlled by US Department of Transportation, Federal Motor Carrier Safety Administration (FMVSS) , Part 571, Standard No. 116; Motor vehicle brake fluids. Brake fluids sold to consumers in bottles/cans etc. or installed in cars sold in NA must conform to the technical specifications detailed in this Standard. The Standard is quite lengthy and covers all the different “types” of fluids which can be used, i.e. DOT3, DOT4, DOT5 and DOT5.1. These different types of fluids all have different requirements per the Standard. It is beyond the scope of this post to delineate the differences between all the different flavors so I will focus on the question fluids DOT4 and DOT5.1.

FMVSS 571.116S5.1.1 defines the term ERBP (Equilibrium Reflux Boiling Point) and gives minimum wet and dry boiling point standards which must be met to be classified in a given DOTx category. See table below. My key focus over the years of using brake fluid in race cars is the “wet” boiling point as this boiling point value is where the fluid properties go after installation and in-service use. Brake fluid is hygroscopic by nature (absorbs atmospheric water) and as the fluid ages in the vehicle system and absorbs water, its boiling point erodes to the minimum wet boiling point value. Thus always use a new unopened container of brake fluid when flushing or adding fluid to the system.

As you correctly opine, just fill your system with DOT5.1 fluid which offers the best boiling capacity of all the grades. You are right!

Understand FMVSS 571.116 dictates MIMIMUM standards the fluid manufacturer must meet to brand his fluid as DOTx. If he can economically blend a fluid which exceeds all the minimum DOTx requirements, he certainly can do so. And the highly reputable fluid manufacturers certainly do this. I have tabulated a few popular brake fluids (DOT4 and DOT5.1) indicating under which DOTx the fluid is sold, the dry/wet boiling points and cost per liter. Data is pulled from https://www.pegasusautoracing.com/group.asp?GroupID=BRAKEFLUID

As is obvious, all of the selected DOT4 fluids exceed the DOT5.1 standards by a significant amount. In fact the Motul 5.1 fluid while exceeding all the required FMVSS 571.116 boiling point requirements falls way short of what you can get in a DOT4 fluid. The only advantage is the lower cost of the DOT5.1. I typically use the DOT4 Motul RBF600 which offers reasonable price for the highest wet boiling point fluid. I really liked the DOT4 ATE Super Blue Racing fluid (same as Type 200) which had a blue color to the fluid. Someone filed a complaint against this product because as a DOT4 fluid, it did not conform to FMVSS 571.116S5.1.14 Fluid Color and the product is no longer available here in NA. Only the ATE Type 200 (amber color per the Specification) is now available and is a strong candidate due to its properties vs. cost. Castrol SRF does carry a higher wet boiling point fluid at a +74% cost premium on which I choose to pass.

So, Pete that is why I would use one of the many economical DOT4 fluid candidates. Hope this helps and I have not bored our audience.

Pete, I love your technical questions! It shows you are thinking about what I posted and forces me to go back and rethink what I said relative to your question(s). Your questions are certainly valid.

I assume the titanium shims are pretty thin, on the order of .010” to .020”? If so, then the shims are very thin relative to their area, and would not reduce total heat transfer significantly. Your experience seems to bear this out.

Yes, the Girodisc Titanium shims I purchased and tried were on the order of 0.020” – 0.030” thick. From their website, "The problem of brake fluid boiling is simply traced to heat transferring from the rotors and pads directly into the fluid through the caliper pistons. When brake fluid boils, it releases air that is normally part of the molecular structure of the fluid. This air is compressible of course, and the brake pedal goes to the floor instead of moving the caliper pistons. Production cars tend to suffer from this on track days more as they don't usually have the extensive cooling duct and exotic brake materials as true racing cars. True racing only brake calipers generally come with titanium caliper pistons for one reason. Titanium as a material, has low thermal conductivity. This means that it is very bad at transferring heat. Which is good if you are trying to keep your fluid cool.

The Girodisc solution to help prevent fluid boiling is to use a thin titanium shim placed between the pad back and the pistons, to keep the braking heat from transferring into the pistons and fluid. Here is a comparison of materials and their relative thermal conductivity ratings

Titanium 6AL-4V 6.7 W/mk

Steel 52 W/mk

Aluminum 130 W/mk

You can see that Titanium will transfer far less heat than steel and especially aluminum. For cars that are going to see hard or multiple track days, these shims are cheap protection from loosing the pedal due to boiling at the wrong time and making the day very expensive.

Water jet cut to exact size, no cutting, grinding, or swearing involved."

To your point, yes the shims were thin relative to the brake pad friction material (approx 0.47” thick which has a low K value as you correctly point out) and the steel backing plate (approx 0.120”), but the generated BTU’s still flow from the steel backing plate into the caliper pistons (thru conduction reduced somewhat by the low K Titanium shim) and to the caliper structure (thru radiation). Emissivity values for rotor steel (about 0.64) and Titanium shim (0.51 – 0.61) for typical rotor temperatures are about the same but vary due to the material surface finish. Assume radiation heat transfer is a push. So even though the shims are thin, they do provide a barrier to Q (heat flow) into the brake pistons. Note too that the small area which you reference for the shims, is numerically equal to the same area the unshimmed pistons would have contacting the steel backing plate. And my experience did NOT bear out the insignificance of the Titanium heat shield barrier. I did see evidence the generated braking heat was retained in the brake rotor (bluing steel) and thermal indications on the pad material. So even though the shims are relatively thin, they did appear to (as advertised) limit Q into the caliper pistons and caliper brake fluid.

Now onto the brake fluid question, “And why wouldn’t you choose DoT 5.1 over DoT 4?”. Excellent question and I had to think about that one cause using DOT4 just rolled off the top of my head. See also Best DOT 5.1 Brake Fluid of 2021: Reviews & Buying Guide (lastviews.com) As I am sure you know but for members not familiar with brake fluid, all automotive brake fluid used in North America (NA) is controlled by US Department of Transportation, Federal Motor Carrier Safety Administration (FMVSS) , Part 571, Standard No. 116; Motor vehicle brake fluids. Brake fluids sold to consumers in bottles/cans etc. or installed in cars sold in NA must conform to the technical specifications detailed in this Standard. The Standard is quite lengthy and covers all the different “types” of fluids which can be used, i.e. DOT3, DOT4, DOT5 and DOT5.1. These different types of fluids all have different requirements per the Standard. It is beyond the scope of this post to delineate the differences between all the different flavors so I will focus on the question fluids DOT4 and DOT5.1.

FMVSS 571.116S5.1.1 defines the term ERBP (Equilibrium Reflux Boiling Point) and gives minimum wet and dry boiling point standards which must be met to be classified in a given DOTx category. See table below. My key focus over the years of using brake fluid in race cars is the “wet” boiling point as this boiling point value is where the fluid properties go after installation and in-service use. Brake fluid is hygroscopic by nature (absorbs atmospheric water) and as the fluid ages in the vehicle system and absorbs water, its boiling point erodes to the minimum wet boiling point value. Thus always use a new unopened container of brake fluid when flushing or adding fluid to the system.

View attachment 64016

As you correctly opine, just fill your system with DOT5.1 fluid which offers the best boiling capacity of all the grades. You are right!

Understand FMVSS 571.116 dictates MIMIMUM standards the fluid manufacturer must meet to brand his fluid as DOTx. If he can economically blend a fluid which exceeds all the minimum DOTx requirements, he certainly can do so. And the highly reputable fluid manufacturers certainly do this. I have tabulated a few popular brake fluids (DOT4 and DOT5.1) indicating under which DOTx the fluid is sold, the dry/wet boiling points and cost per liter. Data is pulled from https://www.pegasusautoracing.com/group.asp?GroupID=BRAKEFLUID

View attachment 64017

As is obvious, all of the selected DOT4 fluids exceed the DOT5.1 standards by a significant amount. In fact the Motul 5.1 fluid while exceeding all the required FMVSS 571.116 boiling point requirements falls way short of what you can get in a DOT4 fluid. The only advantage is the lower cost of the DOT5.1. I typically use the DOT4 Motul RBF600 which offers reasonable price for the highest wet boiling point fluid. I really liked the DOT4 ATE Super Blue Racing fluid (same as Type 200) which had a blue color to the fluid. Someone filed a complaint against this product because as a DOT4 fluid, it did not conform to FMVSS 571.116S5.1.14 Fluid Color and the product is no longer available here in NA. Only the ATE Type 200 (amber color per the Specification) is now available and is a strong candidate due to its properties vs. cost. Castrol SRF does carry a higher wet boiling point fluid at a +74% cost premium on which I choose to pass.

So, Pete that is why I would use one of the many economical DOT4 fluid candidates. Hope this helps and I have not bored our audience.

I could be wrong, but,

Did I read somewhere that the higher the boiling point, the faster the water absorbtion/degredation of the fluid?

Indy, thanks for the detailed reply. Yup, brakes are all about heat management. Just out of curiosity, I looked up the K value for several grades of stainless steels, since I recall that they are significantly lower than for carbon steel. Depending on the grade and operating temperature, it’s around 20 W/mK, somewhat higher than titanium. So scratch the idea of substituting SS for Ti shims (although they would be cheaper and easier to work with).

I’m also aware that the specs on the fluid often exceed the published minimum spec, and in perusing the shelves at the auto parts stores, I’ve also noted that some brands of DoT4 fluids are better than generic DoT5.1 stuff, so I do check the labels on the cans. I think I bought a version of Castrol last time, but it wasn’t the SRF because it wasn’t that expensive. I’ll consider the Motul RBF 600 next time. And I definitely agree that wet boiling point is of greatest importance on a street car that will have its brake fluid for 2-3 years between changes. On a race car, you change it much more often.

Other factors in brake fluids include corrosion inhibitors and resistance to absorbing water. You may know how those are measured and rated, but that’s beyond what I can find on the package!

I’m also aware that the specs on the fluid often exceed the published minimum spec, and in perusing the shelves at the auto parts stores, I’ve also noted that some brands of DoT4 fluids are better than generic DoT5.1 stuff, so I do check the labels on the cans. I think I bought a version of Castrol last time, but it wasn’t the SRF because it wasn’t that expensive. I’ll consider the Motul RBF 600 next time. And I definitely agree that wet boiling point is of greatest importance on a street car that will have its brake fluid for 2-3 years between changes. On a race car, you change it much more often.

Other factors in brake fluids include corrosion inhibitors and resistance to absorbing water. You may know how those are measured and rated, but that’s beyond what I can find on the package!

I could be wrong, but,

Did I read somewhere that the higher the boiling point, the faster the water absorbtion/degredation of the fluid?

GT@50, I am not aware of any studies of water absorption rate vs. time for brake fluid. I would imagine the study would have many different variables like location (Florida vs. North Dakota), caliper/master seal integrity, sitting static or driven, driven in rain, etc. My advice just change the fluid on a periodic basis based on driving application (daily driver vs. racecar).

Excellent questions/writeup and technical explanations. Thank you.

Reviewing the tech data sheets for Motul 5.1 . It seems to indicate that the 5.1 standard offers high performance brake fluid protection( close to the ATE 200 spec) while reducing the viscosity of the fluid and is optimized for ABS system.

This lower viscosity works better with ABS in the cold, where brake temp normally are not a problem, and then provides good high temp protection during the summer months. (European Manufacture/government driven?) This lower viscosity may be the reason 5.1 fluids don't reach "racing" DOT 4 temp levels.

ATE 200 brake fluid had(has in other countries) a nice system for knowing when you had completely flushed your brake system with the new fluid. Blue to amber , then the next time, amber to blue. Fairly high performance fluid. Nice price point.

Water absorption rates. I think the brake fluid manufactures are probably the only ones that know these figures. And they don't tell anyone!

Bottom line for me, fresh, high quality, high temp brake fluid( DOT4 At The Moment), is what I want in the brake system when approaching any corner at speed with my GT or any other car I'm in.

Don't forget your clutch system on the 05/06 GT's.

Disclaimer: my $.02, YMMV, just my WAG

Reviewing the tech data sheets for Motul 5.1 . It seems to indicate that the 5.1 standard offers high performance brake fluid protection( close to the ATE 200 spec) while reducing the viscosity of the fluid and is optimized for ABS system.

This lower viscosity works better with ABS in the cold, where brake temp normally are not a problem, and then provides good high temp protection during the summer months. (European Manufacture/government driven?) This lower viscosity may be the reason 5.1 fluids don't reach "racing" DOT 4 temp levels.

ATE 200 brake fluid had(has in other countries) a nice system for knowing when you had completely flushed your brake system with the new fluid. Blue to amber , then the next time, amber to blue. Fairly high performance fluid. Nice price point.

Water absorption rates. I think the brake fluid manufactures are probably the only ones that know these figures. And they don't tell anyone!

Bottom line for me, fresh, high quality, high temp brake fluid( DOT4 At The Moment), is what I want in the brake system when approaching any corner at speed with my GT or any other car I'm in.

Don't forget your clutch system on the 05/06 GT's.

Disclaimer: my $.02, YMMV, just my WAG

The system is sealed so absorption shouldn't be too high in the system. Maybe it was corrosiveness. Whatever the other differences are they're probably only noticed in a lab and/or systems that aren't maintained.GT@50, I am not aware of any studies of water absorption rate vs. time for brake fluid. I would imagine the study would have many different variables like location (Florida vs. North Dakota), caliper/master seal integrity, sitting static or driven, driven in rain, etc. My advice just change the fluid on a periodic basis based on driving application (daily driver vs. racecar).

I've been using Ford Dot 4. Dry 509F, wet 338F. Not a problem......yet!

Actually the Ford DOT3 and DOT4 fluid is a very good value. I know many racers who use these fluids. And as Mr. McGowan related to me, the whole 05-06 GT Certification program was done on regular Ford DOT3 brake fluid. The development/certification brake testing performed on this car was pretty brutal. And the fluid preformed without any difficulty.

sahlman

Ford GT Team Alumni

Agreed. I pushed one of our CP builds at Road America in stock condition (fluid, pads, rotors) and the brakes performed well with great feel and no fade.Actually the Ford DOT3 and DOT4 fluid is a very good value. I know many racers who use these fluids. And as Mr. McGowan related to me, the whole 05-06 GT Certification program was done on regular Ford DOT3 brake fluid. The development/certification brake testing performed on this car was pretty brutal. And the fluid preformed without any difficulty.

I our 2012 Audi R8 V10 I warped and faded the stock rotors and Endless Blue Pads in 15 minutes at Road America. It was not up to the task and caught me off guard because of the FGT.

The Ferodo pads and Brembo braking system, cooling and fluid in the FGT is a rare fast car that can run at the track and perform well while also running on the street without the squeal of track pads.

sahlman

Ford GT Team Alumni

Thanks Scott.

We as FGT owners are very lucky to have the actual certification/development engineers on our Forum! These guys really know our cars well and can relate stories as above as to the robustness of the car Ford delivered to us owners. Ask him development questions when we are out in Scottsdale.

We as FGT owners are very lucky to have the actual certification/development engineers on our Forum! These guys really know our cars well and can relate stories as above as to the robustness of the car Ford delivered to us owners. Ask him development questions when we are out in Scottsdale.